The benefit is fewer label nameplate sign or control panel replacements due to illegibility that means guaranteed regulatory compliance asset.

Clear anodized aluminum sheet adhesive backed.

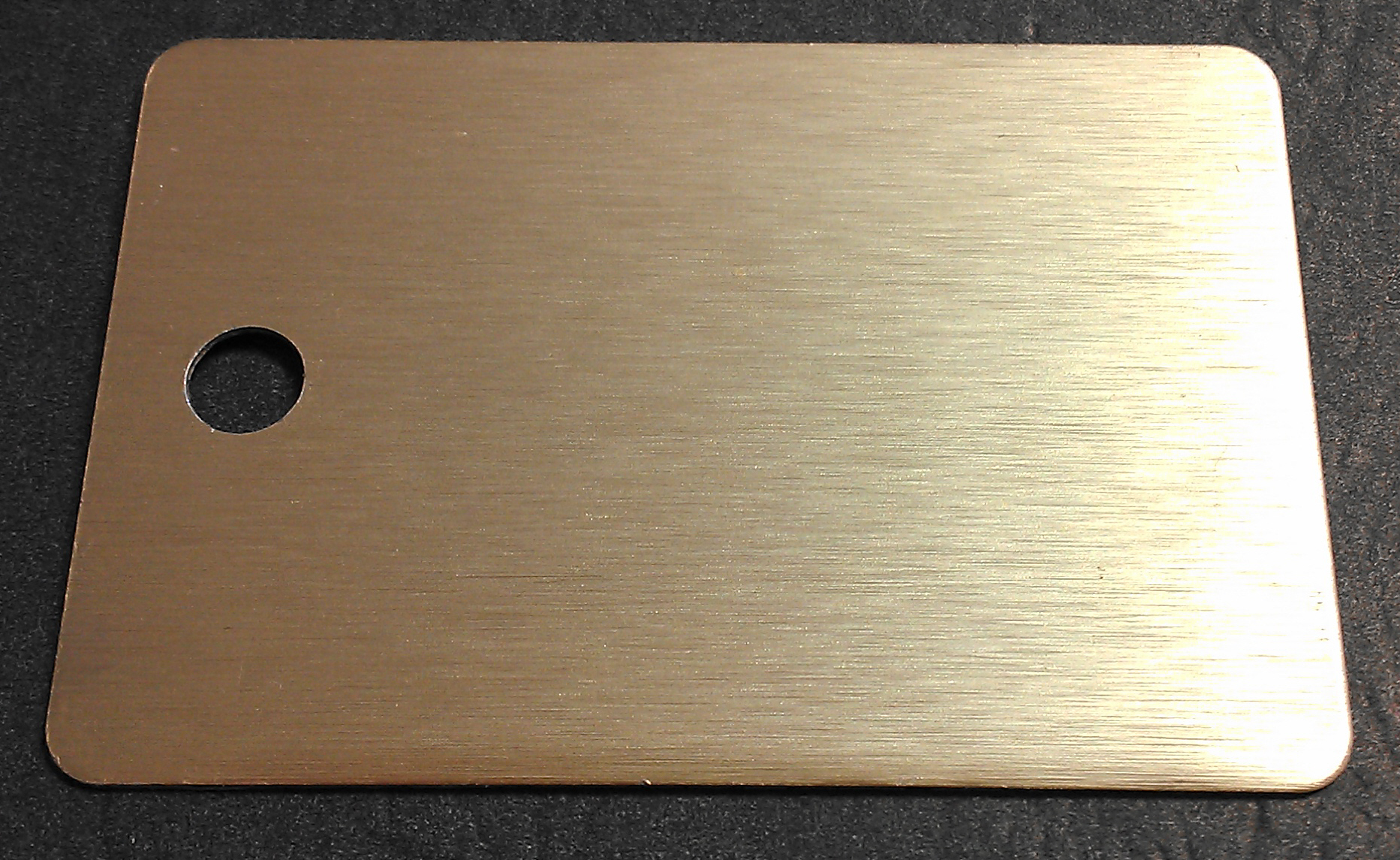

Brite brushed clear anodized aluminum sheet 0 040 brushed smoked anodized aluminum sheet 0 025 clear anodized aluminum sheet 0 063 clear anodized aluminum sheet 0 080 linear wave clear anodized anodized aluminum sheet 0 025 orbital scratch clear anodized anodized aluminum sheet 0 025.

Because of this what is called a rack mark will be made on all anodized pieces.

3 3 out of 5 stars 28.

Stucco patterned metal sheets.

Clear anodized bronze anodized and gold anodized finishes are what most people think of first when considering aluminum.

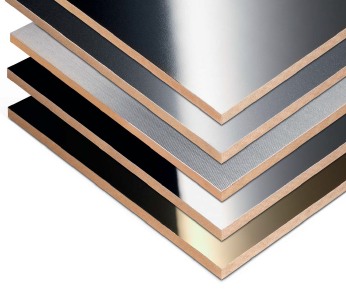

White baked enamel steel.

Polished to either a brushed or mirror like finish this material is widely used to fabricate decorative enclosures and industrial workstations.

Or fax us at.

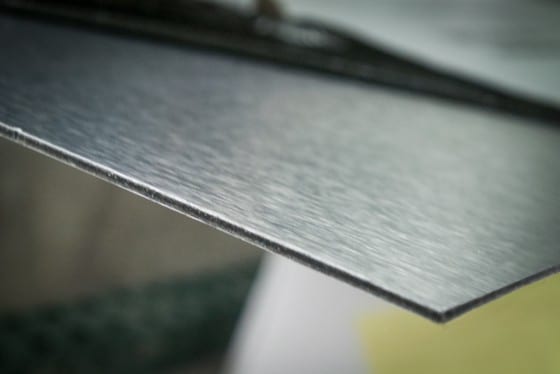

The polished surfaces are covered with a protective peel off film.

An anodized coating bonds to the aluminum surface to improve wear and corrosion resistance.

Metalphoto s archival silver halide based image is sealed inside of anodized aluminum making it readable after prolonged exposure to a variety of harsh operating conditions including weather sunlight heat abrasion chemicals and salt spray.

Frequently asked questions about anodized aluminum.

Aluminum anodized clear sheets.

The most widely used aluminum 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts.

An anodized coating bonds to the aluminum surface to improve wear and corrosion resistance.

It maintains its corrosion resistance in temperatures up to 1500 f.

During the anodizing process electrical contact must be made at all times with the material being anodized.

It is strong and corrosion resistant plus it s easy to machine and weld.

Wrisco delivers those finishes in the most beautiful variations available bright matte clear brush stroked and more.

It is strong and corrosion resistant plus it s easy to machine and weld.

The most widely used aluminum 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts.

Anodized aluminum can accurately present the same classic appearances of other popular metals including copper brass bronze and stainless steel.

Aluminum anodized bronze black anodize.

Why is there a mark on full sheets or full length extrusions.

It is strong and corrosion resistant plus it s easy to machine and weld.

The most widely used aluminum 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts.

617 282 1150 or 800 841 9442.